FOX-XP

The FOX-XP system offers a versatile test and burn-in solution for full wafer testing with WaferPak Contactors. Enhance throughput with the optional FOX-XP WaferPak Aligner, streamlining wafer alignment into FOX WaferPak Contactors.

Aehr Test Systems delivers comprehensive production wafer testing solutions, enhancing yield and reliability throughout your product manufacturing process.

FOX-XP with Automatic WaferPak Aligner

Advanced Test System for Multiple Wafers with Automatic Wafer Handling System

Efficient High-Throughput Automated Solution for Burn-in and Testing of Logic, Memory, Photonic, and Power Devices

- Optimized High-Throughput System for Reliability Verification and Testing in Volume Production

- Accommodates full wafers, panels, singulated dies, and modules, maximizing production efficiency.

- Detects defects in logic, memory, photonic, and power dies before final packaging integration.

- Up to 18 Blades (slots) for wafer or panel examination using WaferPak™ contactors.

- Supports up to 9 Blades for precise testing of wafer, singulated die and module DiePak® carriers.

- Advanced high-power testing capability with up to 3,500 watts of power per wafer

- Flexible Channel Resource Configuration for Enhanced Versatility

- Each Blade (slot) supports various resource modules: Universal Channel Modules, High Voltage Channel Modules, and High Current Channel Modules.

- Offers up to 2,048 Universal Channel resources per Blade, including I/O, Clock, PPMU, and DPS, with deep scan, pattern data, and capture memory per channel for testing devices with BIST/DFT capabilities.

- Provides up to 1,024 resources per Blade for high voltage (up to 29V) and high current (up to 2A) source requirements.

- Production Proven Full-Wafer Reliability Verification & Test Solution

- Lowers testing expenses by enabling functional testing of wafers, dies, and modules during the reliability verification process.

- Provides a comprehensive solution when equipped with a WaferPak contactor or DiePak carrier, complemented by a Wafer Aligner or DiePak Loader.

- Ensures device safety with individual per-channel protection against over-current and over-voltage incidents.

- Integrated Automated Wafer Handling and Alignment System

- Fully automated material handling in a hands-free operation.

- Compatible with wafers up to 300 mm in size for handling and alignment.

- Fully integrated with FOX-XP Systems.

FOX-XP

Advanced Test System for Multiple Wafers and Individual Die/Modules

Efficient High-Throughput Solution for Burn-in and Testing of Logic, Memory, Photonic, and Power Devices

- Optimized High-Throughput System for Reliability Verification and Testing in Volume Production

- Accommodates full wafers, panels, singulated dies, and modules, maximizing production efficiency.

- Detects defects in logic, memory, photonic, and power dies before final packaging integration.

- Up to 18 Blades (slots) for wafer or panel examination using WaferPak™ contactors.

- Supports up to 9 Blades for precise testing of wafer, singulated die and module DiePak® carriers.

- Advanced high-power testing capability with up to 3,500 watts of power per wafer

- Flexible Channel Resource Configuration for Enhanced Versatility

- Each Blade (slot) supports various resource modules: Universal Channel Modules, High Voltage Channel Modules, and High Current Channel Modules.

- Offers up to 2,048 Universal Channel resources per Blade, including I/O, Clock, PPMU, and DPS, with deep scan, pattern data, and capture memory per channel for testing devices with BIST/DFT capabilities.

- Provides up to 1,024 resources per Blade for high voltage (up to 29V) and high current (up to 2A) source requirements.

- Production Proven Full-Wafer Reliability Verification & Test Solution

- Lowers testing expenses by enabling functional testing of wafers, dies, and modules during the reliability verification process.

- Provides a comprehensive solution when equipped with a WaferPak contactor or DiePak carrier, complemented by a Wafer Aligner or DiePak Loader.

- Ensures device safety with individual per-channel protection against over-current and over-voltage incidents.

FOX-NP

Comprehensive Test System for Full Wafers and Individual Die/Modules

Compact and High-Power Testing and Reliability Verification Solution for Logic, Memory, Photonic, and Power Devices

- Compact and Versatile High-Throughput Solution for Reliability Verification and Testing

- Capable of handling applications involving full wafers, panels, singulated dies, and modules.

- Efficiently detects failures in logic, memory, photonic, and power dies prior to final package integration.

- Features a high-power thermal chuck with dual Blade (slot) capability, compatible with WaferPak™ contactors or DiePak® carriers for singulated die or module testing.

- Economical High Power Wafer, Die, and Module Verification and Test Solution

- Versatile channel resource configurations per Blade (slot), including Universal Channel Modules, High Voltage Channel Modules, or High Current Channel Modules.

- Features up to 2,048 Universal Channel resources per Blade, encompassing I/O, Clock, PPMU, and DPS, equipped with deep scan, pattern data, and capture memory for each channel, ideal for testing devices with BIST/DFT.

- Provides up to 1,024 high voltage (up to 29V) or high current (up to 2A) source resources per Blade.

- Production Proven Full-Wafer Reliability Verification & Test Solution

- Decreases testing expenses by enabling functional testing of wafers, dies, and modules during the reliability verification phase.

- Provides an all-encompassing solution when set up with a WaferPak contactor or DiePak carrier, along with a Wafer Aligner or DiePak Loader.

- Ensures device safety with individual per-channel protection against over-current and over-voltage.

Automatic WaferPak Aligner

Wafer Loader/Unloader for FOX WaferPak Contactors

- Automated Solution for Loading, Aligning and Unloading of Wafers

- Loads and unloads wafers between FOUPs or cassettes and WaferPak contactors

- Dual FOUP/cassette interface enables automated handling of up to 50 wafers

- Handles and aligns up to 300 mm wafer sizes

- May be used with a FOX-XP or FOX-15 System

- Production Proven Full-Wafer Burn-in & Test Solution

- Based upon an industry-leading wafer prober platform

- Optical bar code reading of FOUPs, Wafer IDs and WaferPak contactor IDs for error free operation and wafer traceability

- May be integrated with a factory automated material handling systems

- Precision Wafer Handling and Pad to Probe Alignment

- Optical alignment via multiple cameras assures correct wafer to probe alignment and placement in a WaferPak contactor

- Integrated Solution with FOX-XP system

- Enables automated selection of test program based on wafer/lot ID

- Shares traceability of wafers and test results with FOX-XP system

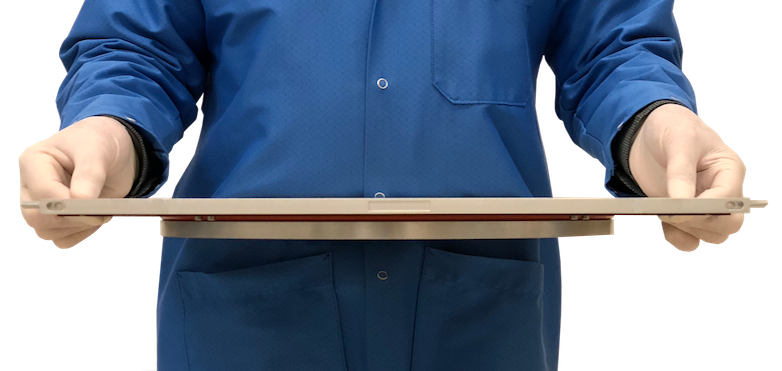

FOX-XP WaferPak Contactor

Efficient Single Touchdown System for Full-Wafer Testing and Burn-in

- Optimized Delivery of FOX-XP System Resources for Single Touchdown Wafer Testing and Burn-in

- Configurable for wafers up to 300 mm in size.

- Demonstrated production reliability with over 50,000 contacts per wafer.

- Compatible with various pad metallurgies including Aluminum (Al), Copper (Cu), Gold (Au), or solder balls.

- Operates across a temperature range from ambient to 150° C.

- Enhanced Channel and Power Handling Capabilities

- Supports up to 2,048 I/O and DPS channels, featuring remote voltage and ground sense for each pin.

- Capable of handling up to 4 amps per contact.

- Capable of Managing up to 2 Kilowatts of Power Dissipation

- Facilitates High-Volume Full Wafer Production Testing and Burn-in with a Single Touchdown Approach

- Carrier Designed for Easy Field Repairability